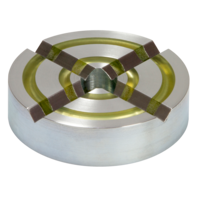

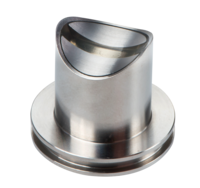

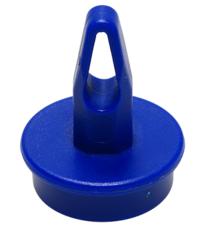

Modified standard systems

When it comes to customised products, we offer our customers individual product configurations that not only fulfil their purpose, but also represent a real solution to a problem. It is often sufficient to modify an existing magnet system in the product catalogue.

Experience the power of customisation and let your vision become reality!

Examples of magnetic solutions, customised for your vision!

Are you looking for the perfect magnetic solution? Then BRUGGER is the right place for you!

BRUGGER is your partner for innovative solutions. Our huge portfolio of standard magnetic systems forms the basis for customised and high-performance applications. Whether small or large, we customise our products to your requirements - thanks to state-of-the-art production technologies in-house.

Brugger takes care of everything: from consultation and development to the completion of your customised magnetic solution!

Our flexible assembly department combines bonding, pressing, riveting and assembly under one roof. This enables us to realise complex assemblies with maximum precision.

Our expertise makes the difference:

-

CNC lathes: For maximum precision and the most complex shapes.

-

EDM machines: To realise the smallest details and individual contours.

-

Punching and pressing tools: For efficient series production and complex geometries.

-

Riveting tools: For stable and durable connections.

Experience the power of customisation. Get in touch with us!

We basically differentiate between two categories of special systems:

- The modification of existing products. The original shape and design (standard programme) are retained. Adaptations in terms of height, length, diameter, surface, adaptation, adhesive force and material are possible. Depending on the extent of the customisation, these can be manufactured from existing standard components. The advantage here is the short delivery time and cost-effective production of small batches.

- New development of customised products. Many applications require the optimum solution. We are your competent partner for this. We have many years of experience in magnet, metal and plastic processing. With our high level of vertical integration and high-performance machinery, we can develop the optimum system solution for you. With our own tool and prototype construction, we support you from sample to series production.

Our claim and our advantage

We have all the necessary production facilities in-house. We can offer the customer everything, regardless of material (e.g. metal or plastic housing), quantity and production. We are so versatile because we also have all the technical expertise in-house, as well as all the necessary machines and production methods. It does not necessarily have to be a product with a magnet - we are at your side with help and advice.

Do you have any questions or would you like specific technical advice on possible customised magnetic systems for your application? Please contact us:

Stephan Zenner

Sales Consultant - Technical Application Consultant

Responsibility: Germany (zip codes 6/7/8/9/0), Croatia, Austria, Switzerland, Slovakia, Slovenia, Czech Republic and Hungary.

Robert Stuhlberg

Sales Consultant - Technical Application Consultant

Responsibility: Germany (zip codes 1-5), Europe, Asia, Africa, America, Oceania